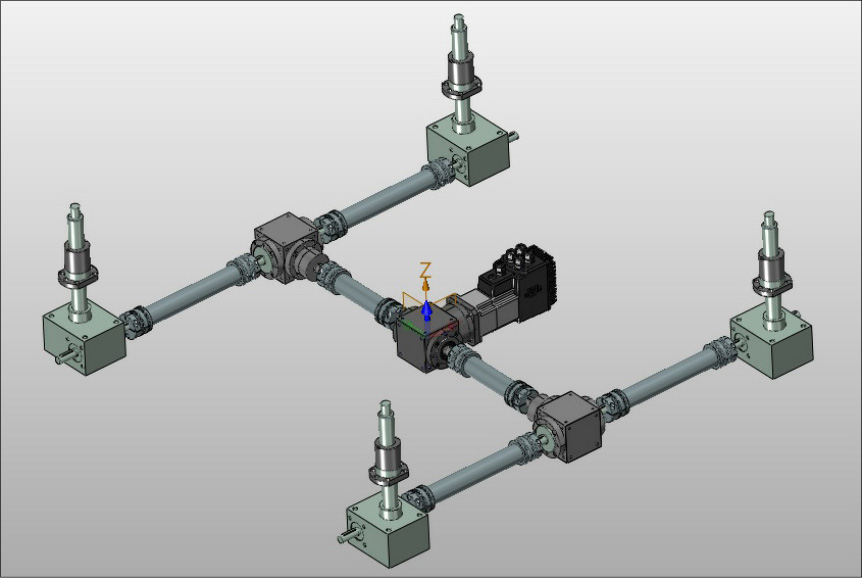

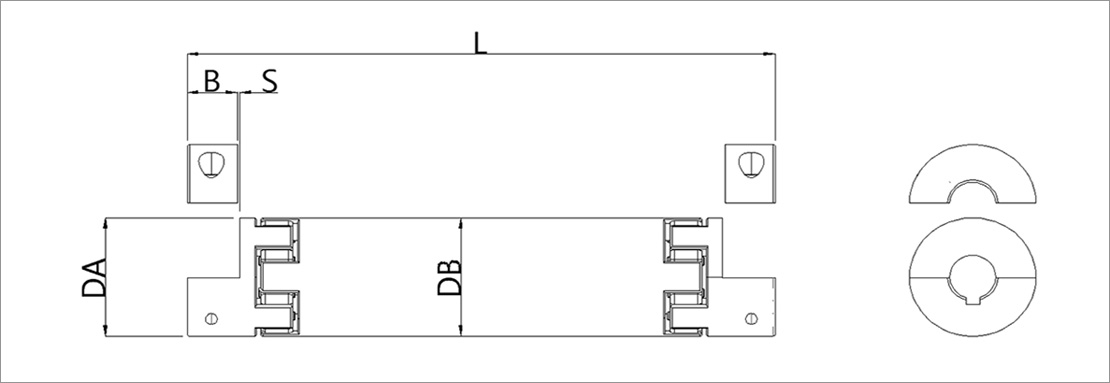

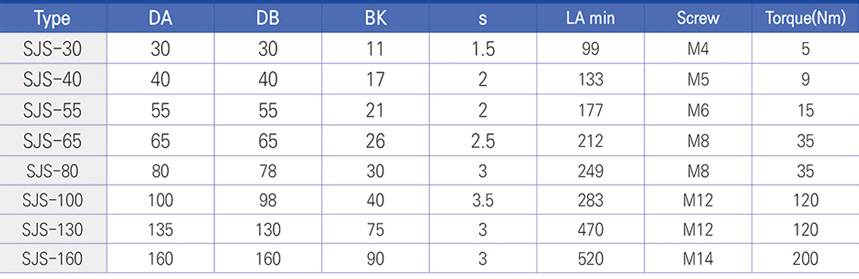

Therefore, when using a reducer, the 15 degree/reduction ratio becomes the assembly error range for the keys of both shafts

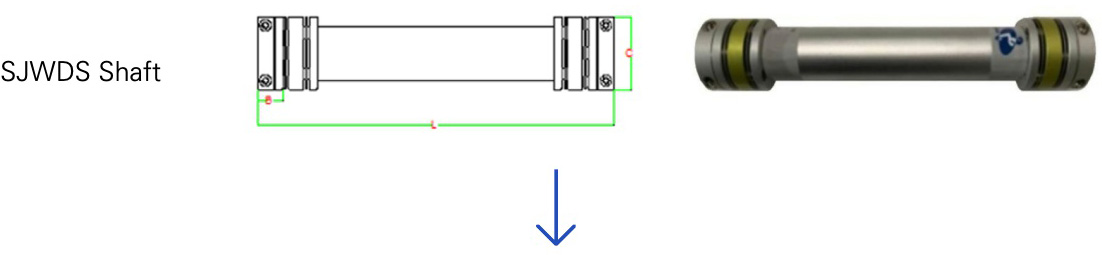

Feature

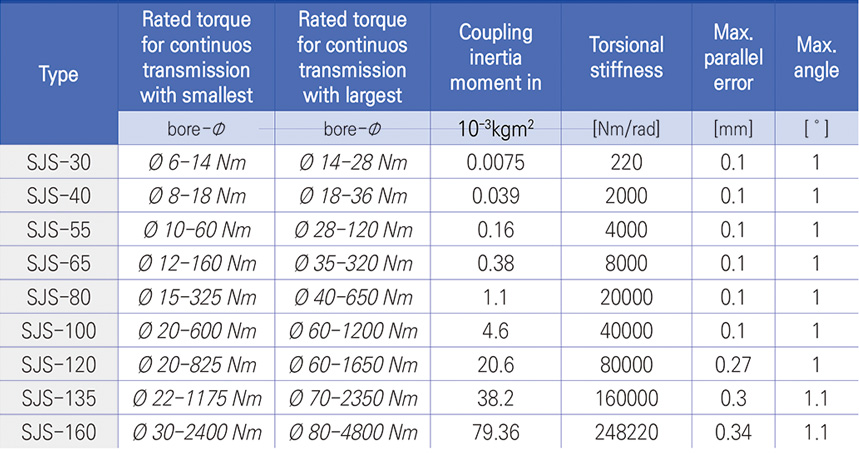

a Seperation type for coupling and pipe

b Existing ket seat

c Screwed with set screws at the end of the shaft

d Instal polyurethane sleeve

e occur twsting when assemble

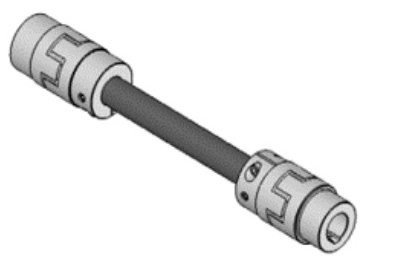

Insert two couplings into the shaft at both ends. Complete to assemble by screwed bolts after drilling and tapping.

Feature

- Work on the assembly site

- If one axis is required on rotate due to the change in the position of the part receiving the load, it must be reassembled.

- Materials may need to be changed during production.

- Able to keep durable.

- Difficult to machine while mounted.

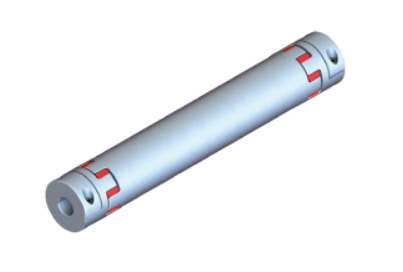

Feature

a Coupling and pipe with all-in-one design(machining)

b Screwed with using a bolt at the end of the shaft

c Installed polyurethane sleeve

(High torque performence, low misalignment-compared to the outside diameter)

d No keys

e No twisting when assemble

파이프와 커플링의 몸체를 CNC에서 필요한 길이마다 한번에 가공함

Feature

- Consume high cost and time

- No keyway to avoid reassemble.

- Occur slip due to tolerance if use only clamp excluding keyway.

- Difficult to machine while mounted.

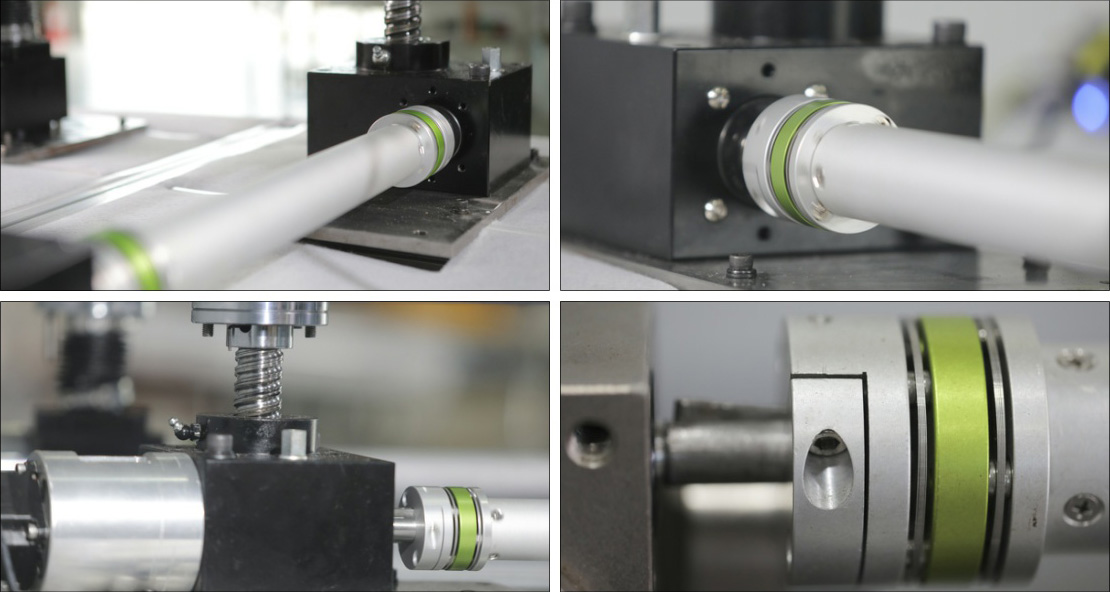

Simply assmeble in field · Avoid damage to the shaft end

Able to assemble in clean room

Remove slip · Increase durable

Increase safety

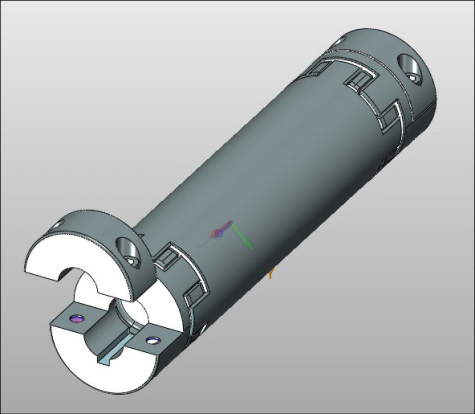

Feature

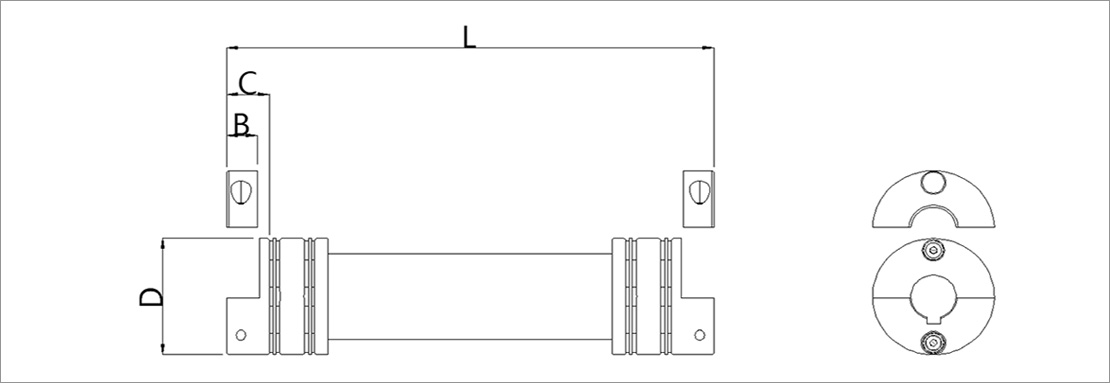

1 Coupling and pipe with all-in-one design

b Existing keyway

3 Screw bolts at the end of shaft(x2)

4 Install polyurethane sleeve

d occur torsion when assemble

Pipe attachment - Save cost and time

Able to supply by removing the clamp : Able to assemble in field by final assmeble without work.

Able to occured torsion : Twisted stiffiness cannot be avoided when each coupling keyway is inserted into the shaft at both ends.

- Removed Hub(Length of Bk) and machining keyway is standard spec.

- Using a material with high stiffiness among polyurethane, the torque performance is very good compared to the outside diameter.

Change the reason of torsion · Change the coupling · Minimize torsion

Increase efficiency

Feature

a and pipe with all-in-one design

b Existing keyway

3 Screw bolts at the end of shaft(x2)

5 Minimize torsion due to assembled

6 Insert double disk(High misalignment

increase in torque by incresing the outside diameter

Minimize torsion

- Level the load, and increase convenience to assemble by bolt it last.

- When inserting couplings on both keyways, the torsion error range is within about 15 degrees.

- When using a reducer, 15 degree/reduction ratio becomes the assembly error range of Load Level.

Increase offcenter and angle of deviation endplay by at least 1.5 to 3 times through assemble two double disk couples.

(Listed minimum value in the catalog)

- Remove the clamp, fix the reducer shaft with 2 screws, STS material available.

- Better compensation of both offcenter and angle of deviation, Changable position of keyway

- Minimize tension during assembly. when applied to a narrow space, the position of the shaft end of the reducer can be arranged between b and c.

- Double discs can be used on both sides, in which case offcenter and angle of deviation are allowed more than doubled.